Lightweight turntable positioners - TRK SERIES

The TRK machines are welding bench and welding column positioners for manual and automatic welding of circular devices ranging from 70 kg to 150 kg. All TRK can be tilted from 0° to 90° with mechanical positioning every 10° and variable rotation speed through a potentiometer.

For these series of welding positioners, which includes a pedal in the machine for the start and stop drivers, the MECOME has available two types of control:

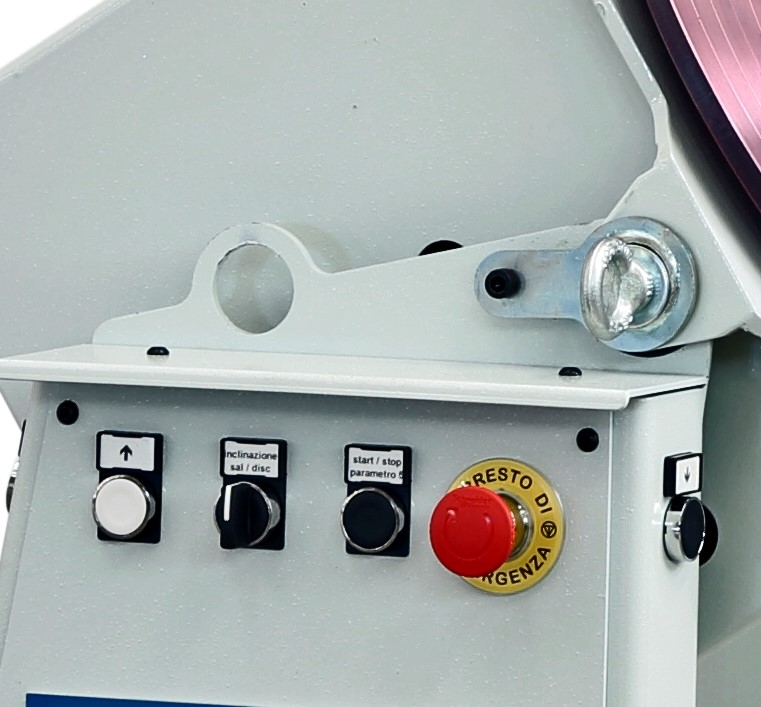

BASE CONTROL BOARD

- Luminous start/stop switch

- Button for start / stop rotation

- Potentiometer for rotational speed adjustment with digital display

- Selector for clockwise/anticlockwise rotation

- Selector for 360° stroke end exclusion

- Selector 2/4 times

- Arrangement to be upgraded to MULTIFUNCTION with active green buttons

MULTIFUNCTION CONTROL BOARD

additional features:

- Selector for welding power source 1

- Selector for welding power source 2

- Selector for manual/auto cycle

- Button for up/down pneumatic arm torch support

- Button to insert Start delay

- Button to insert Welding overlap with digital display

- Button to insert End welding fading

SCHEDA DI CONTROLLO

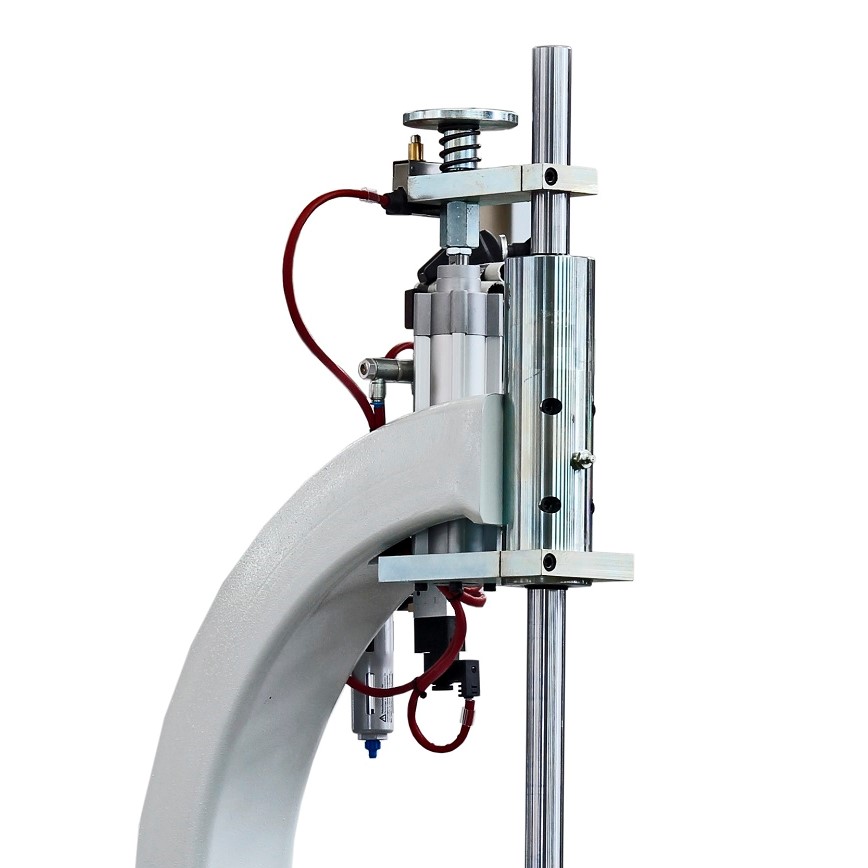

Just for this option the client can order an accessory as a torchbearer swingarm with automatic release.

All TRK bench positioners are provided with shielding for the high frequency TIG welding generators.

The model TRK150C is complete with pneumatic tailstock for locking the part to weld and includes automatic leaning system (with fi xed speed).

TRK SERIES' PRODUCTS

TRK 35 OUT OF PRODUCTION

TRK 70

TRK Column positioner for manual/automatic welding of circular pieces, with a payload of 70 kg. when the table is in horizontal position.

Plate rotation with a D.C. gearmotor complete with electronic feedback control and with speed adjustable by potentiometer.

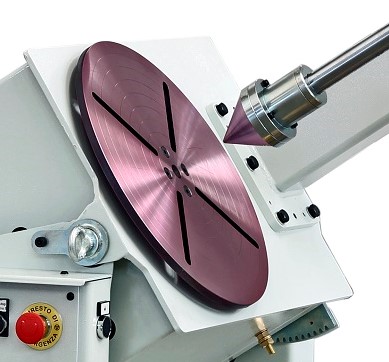

Tilting table from 0° to 90° with manual lock position and central reference in H7 with n. 4 grooves for an easy fixing of the jigs for piece locking.

For TRK70 lightweight turntable table positioner two control boards are available BASE and MULTIFUNCTION with all the functions controlled on the user’s friendly front panel and complete with rotation start/stop pedal.

TRK 150

Column positioner for manual/automatic welding of circular pieces, with a payload of 150 kg. when the table is in horizontal position.

Plate rotation with a D.C. gearmotor complete with electronic feedback control and with speed adjustable by potentiometer.

Tilting table from 0° to 90° with manual lock position and central reference in H7 with n. 4 grooves for an easy fixing of the jigs for piece locking.

For this type of table positioner two control boards are available BASE and MULTIFUNCTION with all the functions controlled on the user’s friendly front panel and complete with rotation start/stop pedal.

TRK 150C

Column positioner with a pneumatic tailstock for fixing and for manual/automatic welding of circular pieces, with a payload of 150 kg. when the table is in horizontal and vertical position.

Plate rotation with a D.C. gearmotor complete with electronic feedback control and with speed adjustable by potentiometer.

Tilting table from 0° to 90° with a D.C. gearmotor at fixed speed and complete with central reference in H7 and with n. 4 grooves for an easy fixing of the jigs for piece locking.

All the functions of TRK 150C are controlled by the MULTIFUNCTION board (for the description of each function see page 4) on the user’s friendly front panel and complete with movable console where are placed bi-manual buttons for tailstock closing and selector for tilting adjustment.

|

|

|

|

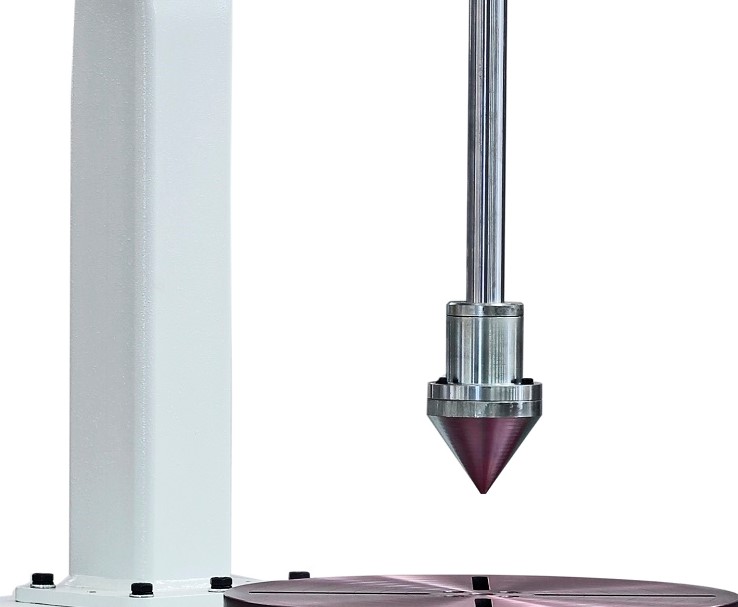

| Pneumatic tailstock with micro switch for piece presence detection |

Idle tailstock | Motorized tilting from 0° to 90° | Plate with grooves and central reference |

Pneumatic tailstock with micro switch for piece presence detection

Idle tailstock

Motorized tilting from 0° to 90°

Plate with grooves and central reference

TRK 150C

Column positioner with a pneumatic tailstock for fixing and for manual/automatic welding of circular pieces, with a payload of 150 kg. when the table is in horizontal and vertical position.

Plate rotation with a D.C. gearmotor complete with electronic feedback control and with speed adjustable by potentiometer.

Tilting table from 0° to 90° with a D.C. gearmotor at fixed speed and complete with central reference in H7 and with n. 4 grooves for an easy fixing of the jigs for piece locking.

All the functions of TRK 150C are controlled by the MULTIFUNCTION board on the user’s friendly front panel and complete with movable console where are placed bi-manual buttons for tailstock closing and selector for tilting adjustment.

|

|

|

|

| Pneumatic tailstock with micro switch for piece presence detection |

Idle tailstock | Motorized tilting from 0° to 90° | Plate with grooves and central reference |

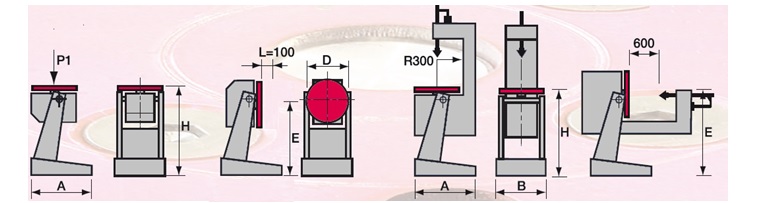

TRK SERIES DIMENSIONS

|

TRK |

A mm |

B mm |

D Ø mm |

E | H | Volt | Rounds rpm |

P1 Kg |

Mf. kgm |

Mt. Kgm |

Weight kg |

|

| TRK 70 | 550 | 475 | 300 | 795 | 855 | 230 | 0.7 -7 | 70 | 5 | 5 | 85 | 660X570X1026 |

| TRK 150 | 635 | 530 | 400 | 855 | 915 | 230 | 0.5 -5 | 150 | 10 | 10 | 90 | 762X636X1099 |

| TRK 150C | 820 | 800 | 400 | 880 | 900 | 230 | 0.5 -5 | 150 | 10 | 10 | 180 | 650X2000X1050 |

WELDING POSITIONER

WELDING PLANTS

MECOME MENU

LEGAL STUFF

MECOME S.R.L.

Via Fornace II strada, 22, 35010 Arsego di San Giorgio delle Pertiche,(PD) Italy

Tel. +39 049 9330425, Fax +39 049 9330434, e-mail: info@mecome.it, PD n. 01145830285, R.E.A. PD n. 188156, CAP. Soc. € 100.000,00 i.v.